Black on Red: My 44 Years Inside the Soviet Union (Review)

Robert Robinson was a black machinist who accepted an offer from the Soviets to leave his job at the Ford plant to come to Russia to help train their machinists in the 1930s. Accepting the deal, he pursued his engineering career and invented many productivity improving tools, acquired a mechanical engineering degree, survived the Purges and World War II, and after the war, spent decades trying to leave. He eventually escaped in 1974 via Uganda, spent some time as a professor, and ultimately regained citizenship in the United States.

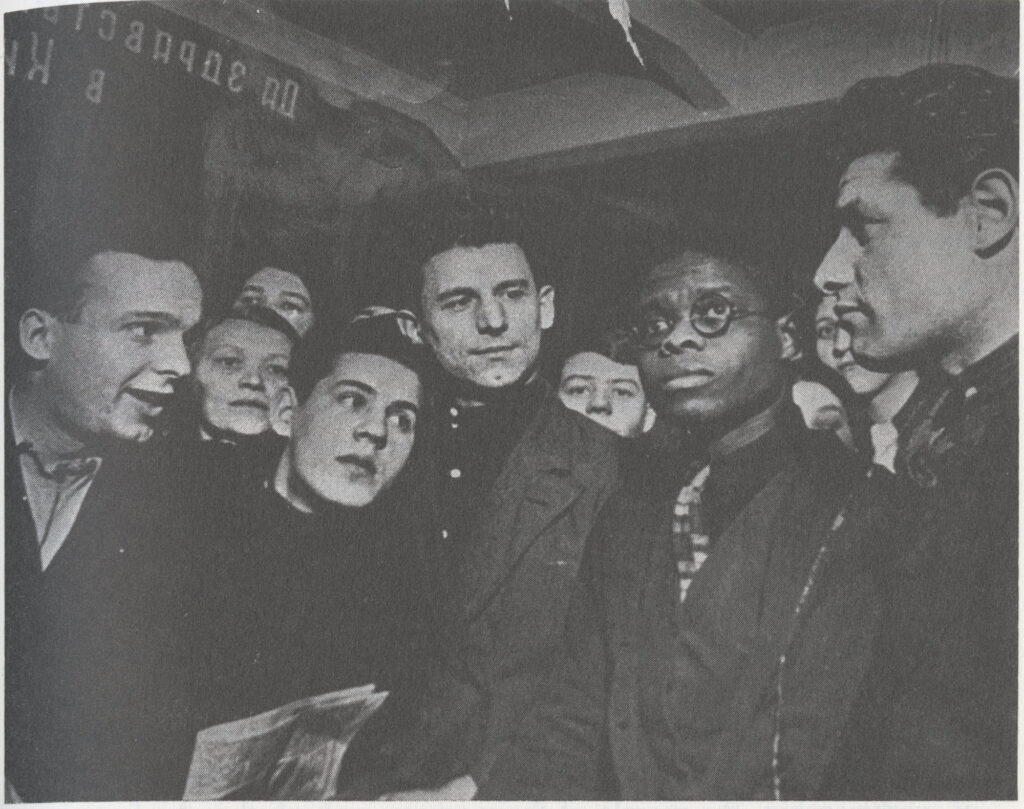

Robert Robinson and Jonathan Slevin. 1988. Black on Red : My 44 Years Inside the Soviet Union : An Autobiography. Washington D.C: Acropolis Books.

As an autobiography, this book details Robinson’s experience with Soviet racism towards him as a black foreigner (even after he gained Soviet citizenship), the surveillance and restrictions on his freedom, as well as the successes and disappointments within his engineering career. Most of the book focuses on his experiences during the 30s and 40s which is when he witnessed the most radical changes in Soviet society. There is a poignant chapter on the Space Race and the Soviet worker’s collapse in morale as the United States pulled ahead. Of the three themes, most reviewers focus on the racism (since his status as a black engineer in Moscow was unique) and his interactions in Soviet Russia (which were far less unique as surveillance and suspicion was pervasive), so I choose to focus on his engineering experience.

Unlike many people who traveled to the Soviet Union in the early 1930s, Robinson was not a fellow traveler, but rather a man who wanted to pursue his chosen profession — engineering. He stayed highly apolitical, partly following his own stated nature and also to avoid helping or angering the authorities. In this, he spent the majority of his life in a ball bearings plant in Moscow, side-by-side with factory workers.

While he was born in Jamaica, Robinson grew up in Cuba. He demonstrated an early talent with machines and became a trained tool maker. Looking for better opportunities, he came to Detroit. Although his resume opened many doors, they were quickly closed once the hiring staff saw him. The trick was you needed an in first, so he took a job sweeping the floor at the Ford plant (a position open to blacks) and then took the internal technical training course. After passing that course (which was redundant given his prior training), he was promoted to a tool making job, although he had to fight sabotage from other workers displeased with his presence. He was the single black among 700 toolmakers.

In April 1930, a Soviet delegation came to the plant to recruit workers for a one year contract. The terms were lucrative (about twice the pay, free housing, free transport to and back, and other amenities) and offered other opportunities, such as tuition for a university education. Robinson had spent three years at Ford and these terms were a promotion – he would be training others in his craft, he had a path towards an engineering degree, and the Soviets promised a lack of Jim Crow. These terms were far better than he could arrange in the United States and he agreed to go.

His initial experiences were positive as he was recognized for his work and found promotions. In contrast to the Americans that traveled to Russia with him, he found the Russians welcoming and friendly, although very poor. He advised other blacks curious about following him that the Russian standard of living was a step below what they were used to, such as reliable hot and cold running water. He renewed his contract many times and returned to Russia after a trip back to the United States in 1933.

Although his intention was to return to the United States within a few years, he found this path blocked. He was being used as a tool of propaganda by the Soviets, and eventually the United States ordered him back home. (The U.S. National Museum of American Diplomacy has documented their version of the events along with additional internal documents.) With the Depression continuing, and his role with the Soviets leading him to be blacklisted in Detroit, he felt there was no employment possibilities awaiting him back in America. He appealed to the Soviet government and, after promising that he could later drop his Soviet citizenship and become American again, became a Soviet citizen. After this, he was trapped.

Throughout his life, Robinson found solace in building, designing, and engineering. His machine shop was a place where he could lose himself within his work and he recounts several inventions that improved productivity at the plant. He continued to work after retirement in Russia, even with a secured pension.

One of the productivity improvements he describes were indicators. The plant owned a small number of mechanical indicators, which were used to ensure the ball bearings were within tolerances. Given the small number of indicators, workers had to queue and wait for them, drastically reducing their output. The indicators (purchased many years ago) were also in Imperial units, but since the specifications were in metric, the measurements had to be translated.

Robinson designed a new indicator that he thought the plant could build. The senior management disagreed, saying the tolerances in his design were beyond their ability. As he was often obliged, Robinson worked on the indicators outside of his scheduled hours and was able to manufacture fourteen specimens. He presented them to management and, after they were validated, the new indicators were adopted by the workers and productivity improved.

Financially, for Robinson’s initiative and additional work (he estimates at 105 working day), he was awarded a twelve day vacation pass and 400 rubles. (Robinson’s account of the resulting vacation is humorous in how regimented and inadequate Soviet rest homes were.) He equates the monetary value to $156 in 1945 dollars. For a median American mechanical engineer, this was less than two weeks of pay.

Unfortunately, the indicators were not to last. After four months, all of the devices were collected and shipped off to be recalibrated. They were dismantled and doused in gasoline, which would have required substantial work to put back together, except they then were lost. The devices likely made their way to the Kalibr Factory which started manufacturing similar devices soon after.

I found his life story to often follow the trajectory of The Ghost of the Executed Engineer. Ghost is a historical work that attempts to answer the question “Given how many engineers and scientists held power in the USSR, why did they trail the West?”. In the early days of the USSR, government policy encouraged Western experts to come in and train workers on Western approaches. The government also invested in Western equipment (Robinson notes that his factory was still using the equipment from the 30s when he left in the 1970s.). Large engineering efforts used humane approaches and volunteers.

However, coincident with the purges, the Soviets adopted a more nationalist approach, believing their techniques and accomplishments superior to the West. Foreigners were no longer welcome, but suspicious; Western-training a mark of corruption. Projects were given less funding and turned to more manual processes and away from machines (e.g. using criminal labor to dig trenches rather than excavators). Economically, the piece-work system (workers were paid by their output, not by their salary) discouraged productivity and quality investments. The purges virtually eliminated the older intelligentsia, eliminating vast amounts of experience and talent.

Fighting these incentives, Robinson’s ambition pushed him to obtain a degree in mechanical engineering which coincided with World War II. To take classes, he traveled six miles across Moscow to the Moscow Evening Institute while the city was being bombed. Moscow had a curfew at 2100, but since his classes ended at 2145, he had to walk the way back. He accounts he was arrested 14 times for breaking curfew.

As this was a Soviet engineering degree, it only included two “liberal education” classes: a history of the Communist party and a course on political economy. Robinson laments that many of his fellow students were narrow-minded and lacked curiosity. As Ghost describes, this was the desired goal per Soviet policy, even though it crippled the typical engineer’s ability to be flexible and innovative.

The degree program was also used a cudgel for industrial policy. A month after being told he had successfully graduated, Robinson went to pick up his diploma. (Soviet diplomas were thick packets of material that described your entire period in college; these could be demanded at will by employers.) Robinson was told that he could only be given his diploma if he accepted a new job with a lesser title than his current title; this new job paid 800 rubles (two-thirds his current pay) and required living in an apartment with three other men (he had a private apartment). He refused and push-back from his plant director eventually allowed him to pick up his diploma. Many of his fellow students were not so lucky; those that refused the job offers became blacklisted from engineering jobs.

The book is riveting and is a useful companion to other works on Soviet history, engineering policy, and the experience of the factory working class. 436 pages.

Where to read it

Black on Red is out-of-print but can be found in used book stores, many libraries, and digitally via the Open Library.